STEP 3D

STEP (STandard for the Exchange of Product model data) is a standard for describing product data. STEP is formally defined in ISO standard 10303. Due to its standardization, it is suitable for data exchange between different systems. In KISSsoft® there is an export to STEP format of the 3D models displayed in the Parasolid viewer. 3D models of cylindrical gears, racks, bevel gears, face gears, helical gears and worm gears can be created and exported.

DXF

AutoCAD DXF (Drawing Interchange Format, or Drawing Exchange Format) is a CAD data file format developed by Autodesk for enabling data interoperability between AutoCAD and other programs. 2D graphics can be output from KISSsoft in DXF format. In addition, a layer can be defined.

IGES 2D

The Initial Graphics Exchange Specification (IGES) is a vendor-neutral file format that allows the digital exchange of information among computer-aided design (CAD) systems. The 2D graphics can be exported in this format.

GAMA

The GAMA XML format is used for Gleason measuring machines and written to a special report. In this format only the main parameters are supported, such as: Normal module, Number of teeth, Helix angle, Facewidth, Profile shift, Root diameter, Start of the involute, Reference diameter , Normal tooth thickness and arc.

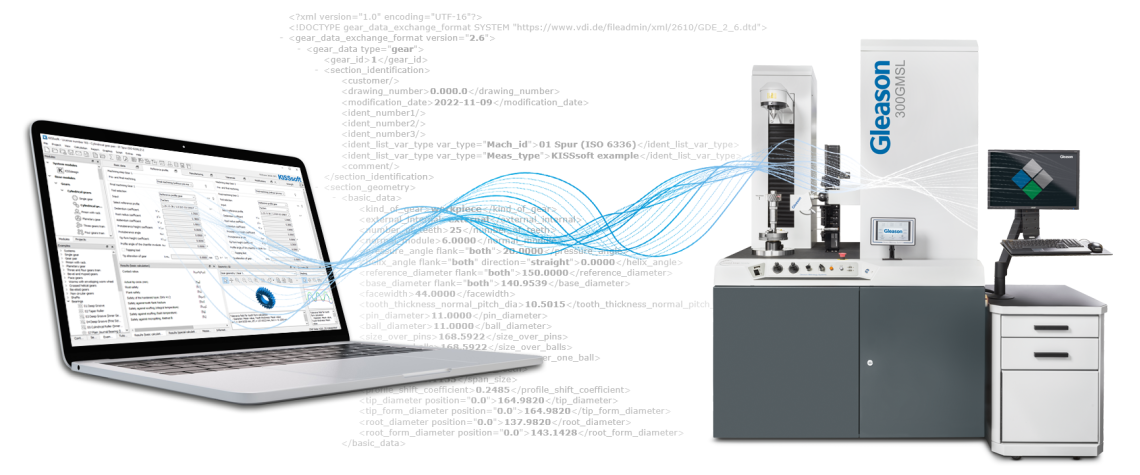

GDE

The standard VDI 2610 defines a flexible data format GDE (Gear data exchange) for gear data based on XML. It allows the transfer and transmission of gear data from design through manufacturing to quality control and quality assurance by electronic means.

FVA e.V., the German Research Institute for Drive Technology, has developed an industry-wide standard for the simple data exchange in gear unit development. The interface is being developed in close cooperation with industry and research under the name REXS (Reusable Engineering EXchange Standard).

GEMS (Gleason Engineering and Manufacturing System) is a design and manufacturing software for Gleason bevel gear design and manufacturing. This interface ensures the import of the geometry of a bevel gear stage from GEMS to KISSsys. With the loads defined, KISSsys can then calculate the bevel gear displacements in the E, P, and G directions and write them out for GEMS. This allows the contact analysis of the bevel gear stage to be performed in GEMS, taking the displacements into account. The results, such as the course of the rotary displacement, meshing stiffness and Hertzian pressure, can be imported into KISSsys and displayed in individual graphs (plots).

The software "Adams Gear AT" is a software system add-on to MD Adams (MBS), which is specialized in the design of gears. By calculating the user real load paths and values within a dynamic transient system simulation. The geometry data of a KISSsys model is written into a format that can be read by MSC Adams Gear AT. This writes out the system data, information on bearings, shaft geometries, connections, loads and gear geometries with the corrections.