Oct 28, 2025

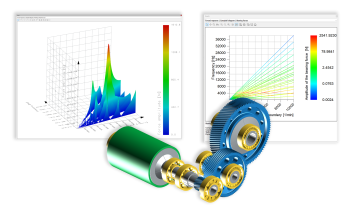

Forced Response analysis in the KISSsoft® System Module enables engineers to calculate the dynamic behavior of drive trains under periodic excitations from multiple sources. Based on the frequency response analysis, this powerful tool allows engineers to evaluate the system responses in terms of amplitudes, frequencies, and phase angles due to the excitations from gear mesh forces, torque ripple and unbalanced mass. This is crucial for understanding how vibrations propagate through gears, shafts and bearings, and for improving NVH performance in electric, hybrid automotive powertrains, industrial gearboxes and others.

The workflow consists of three parts: in a pre-processing step the shaft geometry and gear contacts are analyzed to determine transmission error and nonlinear stiffness as inputs for the excitation forces calculation. In the main step, the forced response calculation generates and solves the coupled vibration equations in a frequency-response framework for a steady state condition, applying excitations from gear mesh, torque ripple, and unbalanced mass. Finally, post-processing delivers gear forces, bearing loads, and shaft responses in time and frequency domains across varying speeds, allowing engineers to capture resonance effects and amplification at critical orders.

Key features

- Settings for gear mesh parameters, stiffness models, and transmission error.

- Single or multiple harmonic excitations, adjustable number of harmonics.

- Ability to include or exclude individual gear pairs as excitation sources.

- Modeling cylindrical, planetary and bevel gears, including systems with coupling or switchable connections.

- Direct import of meshing stiffness for bevel gears from GEMS files.

- Damping models that account for bearings, shafts, and gear meshes.

- Output includes frequency, time and speed domain results for gears, shafts, and bearings.

- 3D visualization of the system deformation, 2D/3D Campbell diagrams across the speed range.

- Exportable data for integration into broader NVH and acoustic simulation workflows.

Key benefits

With forced response analysis, design engineers detect vibration-critical orders, optimize the micro-geometry of gears, and foresee resonant behavior before prototyping. By iteratively evaluating dynamic loads, engineers can design gears that minimize vibration amplification and significantly lower bearing forces fluctuations. This leads to improvements in NVH behavior, enabling quieter, smoother, and more efficient gear transmissions even under demanding operating conditions.

If this topic matters to you, join our webinar on November 4. Register now!

Webinars

Don’t miss our two upcoming webinars in November.

- Dynamic Optimization of a Real-World Gearbox with KISSsoft, November 4, 2025. This webinar explains how KISSsoft’s Forced Response analysis helps engineers identify critical vibration frequencies, assess resonance, and optimize gears and shafts for quieter, more efficient operation. Register now!

- Design Better with KISSsoft and Timken Bearing Expertise, November 18, 2025. This webinar explains Timken rolling bearing fatigue life calculations and shows how to apply them in KISSsoft, using Timken online services and ensuring accurate calculations and reliable fatigue life evaluation. Register now!

Trainings

Profit from the last trainings of this year, dedicated to cylindrical gears:

- Cylindrical Gears: Geometry, Online, German, November 11-12, English, December 01-02.

- Cylindrical Gears: Strength, Online, German, November 13-14, English, December 03-04.

- Cylindrical Gears: Contact analysis, Online, German, November 17-18, English, December 09-10.

Don’t miss these opportunities to expand your expertise – secure your spot today!

Service Pack

The new Service Pack (SP2) for KISSsoft Release 2025 is now available. This update introduces several improvements designed to further streamline and support your engineering design process.