Sep 25, 2025

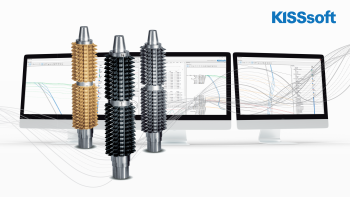

KISSsoft allows users to design the hobbing process for cylindrical gears and the production analysis with tailored calculation and visualization tools.

The new Hobbing module supports defining parameters, including feed rate and cutting speed. It provides a design for a time-optimized hob and the geometry of the gashes. Possible collisions between the tool and the workpiece are visualized in a graphical representation of the hobbing curve and interference contours. Chip thickness and feed marks are determined for the selected parameters.

The service life of the hobbing cutter is derived from the calculated usable tooth length and the tool life in meters. In conjunction with the costs for the hob and the resharpening, the costs per gear are determined. The cutting time and total duration are calculated using the process kinematics.

With the new Rollout calculation and corresponding graphics, KISSsoft provides a precise analysis of cylindrical gear geometry when pre- and final machining are combined. It allows users to check tip and root form diameters, including tolerance evaluation. Tolerances for both workpiece tooth thickness and machining stock can be defined according to industry standards or customized to exact project requirements.

Thanks to the evaluation for minimal, maximal, and user-defined stock, you can assess how cutter tolerances influence the final tooth form. Key parameters such as dFa, dFf, and maximum undercut are calculated to ensure proper meshing.

KISSsoft also offers flexible data input options:

- Define hobs in the “Reference Profile“ tab.

- Check tolerances (mean, min, max) in the “Rollout“ tab using predefined standards or custom values.

- Adjust gear tolerances as needed.

If you wish to learn more about this promising topic, watch our recorded webinar of September 16 on our website or our YouTube channel.

Publications

Read our latest publications, covering topics ranging from the power density and efficiency of plastic gears to the flexibility and performance of the KISSsoft System Module for gearbox design. These articles provide valuable insights into modern gear design techniques and streamlined approaches to precise system design. Read now!

Events

Join us at our upcoming events in October. Discuss with our experts how your design challenges can be solved with KISSsoft Gear Design Software. Meet us at the Motion and Power Technology Expo and the AGMA Fall Technical Meeting, both in Detroit, and learn about a comparative study of the effect of damping on system response:

- MPT – Motion and Power Technology Expo, October 21-23, Detroit, MI, USA.

- FTM – Fall Technical Meeting, October 22-24, Detroit, MI, USA.

Trainings

This October, there are opportunities available for both new KISSsoft users and design engineers with prior KISSsoft knowledge. Acquire or refresh essential skills and knowledge to use the software for shaft and bearing design or enhance your proficiency in bolt calculation.

Don’t miss out – secure your spot today!

- Basic Training: Shafts and Bearings: Modeling, Strength and Lifetime, Online, English, October 06-07.

- Special Training: Bolt Calculation according to VDI 2230, Online, English, October 15-16.