Gear Mesh and Bearing Frequencies, November 15th, 2023

承办: M.Sc. Sebastian Matkovič

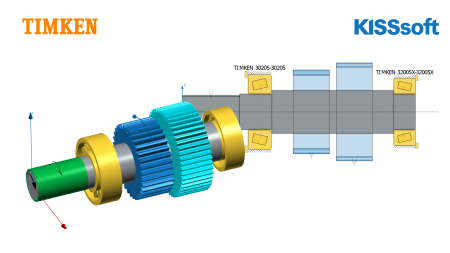

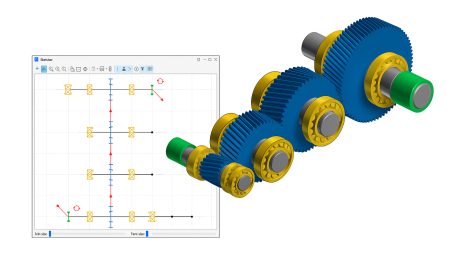

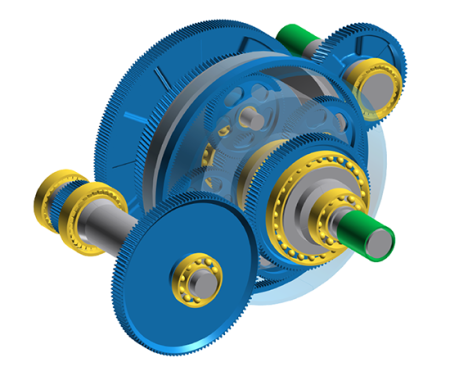

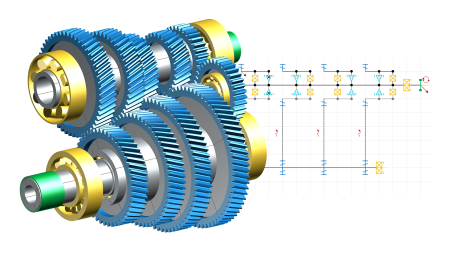

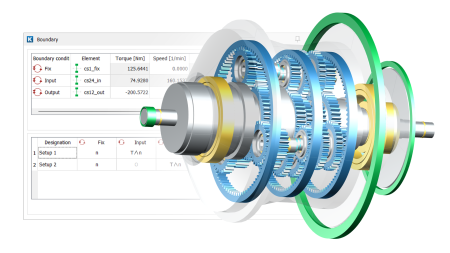

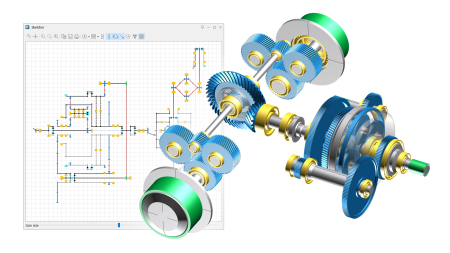

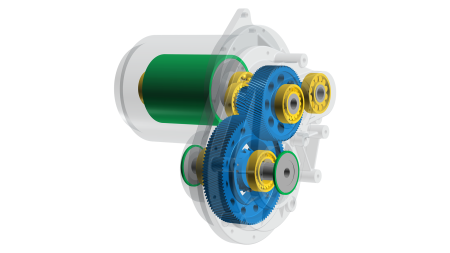

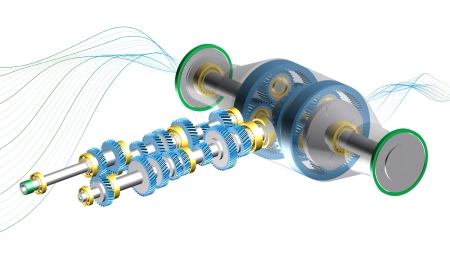

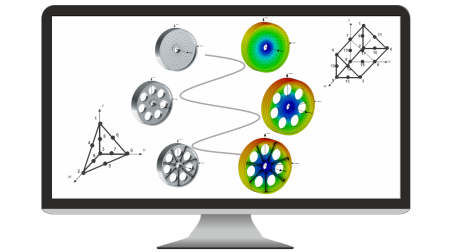

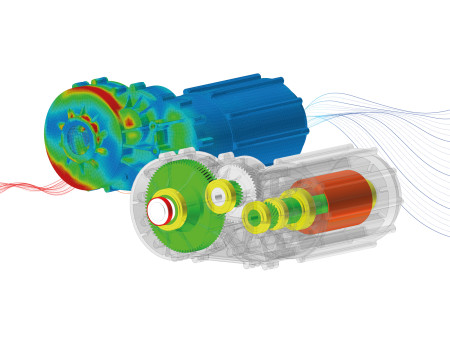

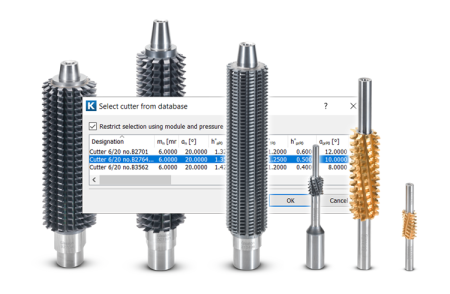

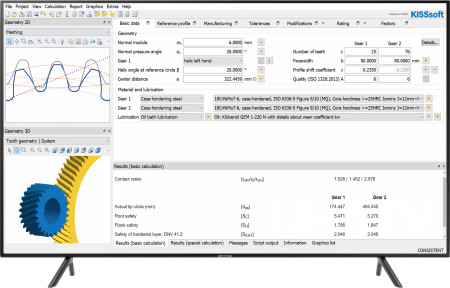

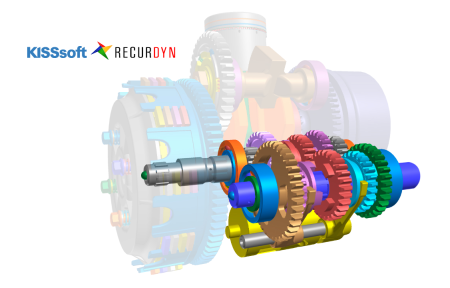

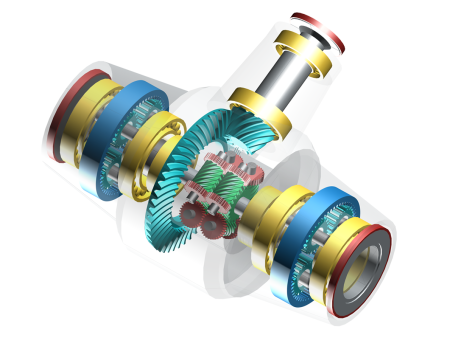

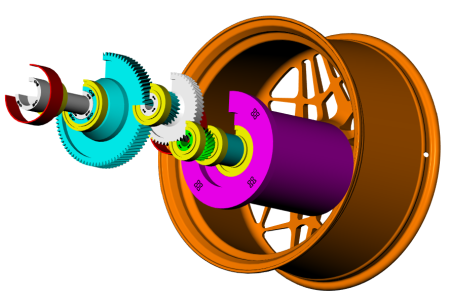

KISSsoft supports the user with numerous calculations for different machine elements. The new KISSdesign® module in KISSsoft® supports the combination of these machine elements in building complex system transmissions containing any number of shafts, gears, and bearings.

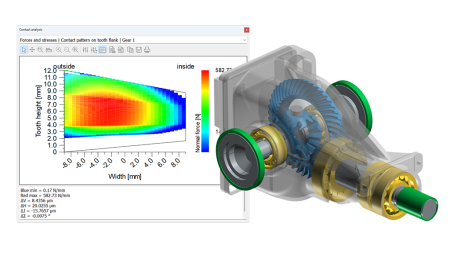

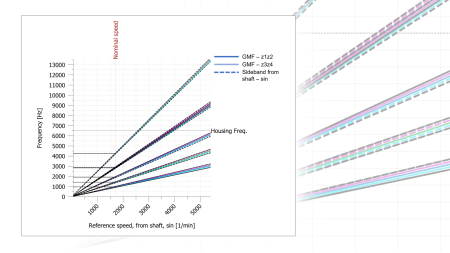

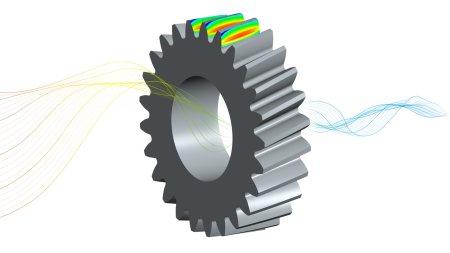

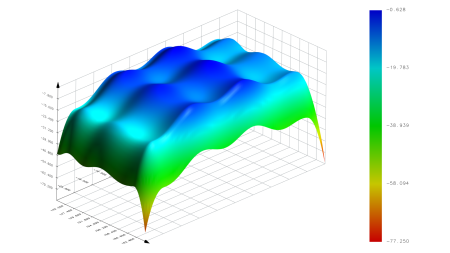

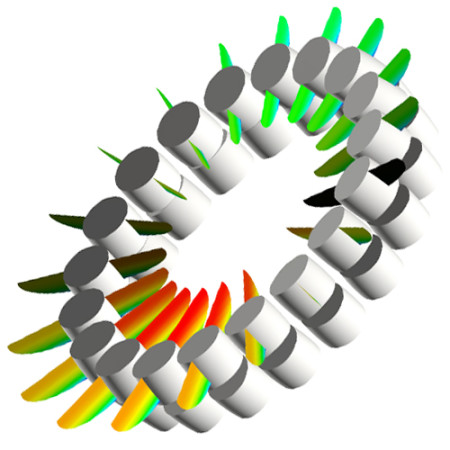

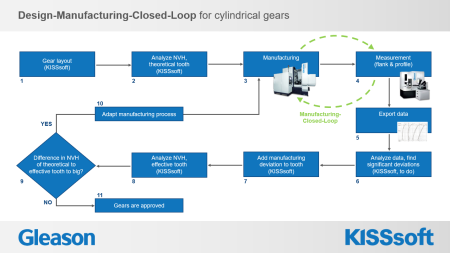

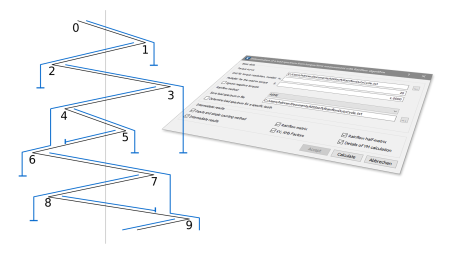

All rotating machine elements contain several characteristic frequencies, which can be one of the potential sources of noise in the transmissions. For example, gear meshing creates vibrations in its meshing frequency due to transmission error, manufacturing deviations, stiffness variation, torque fluctuations, as well as other sources. Therefore, knowledge of the characteristics and frequencies of the transmission can lead to an improved design and contribute to improved diagnostics of an existing transmissions.

During our webinar on November 15, 2023, various possibilities for the calculation of system characteristic frequencies, including gear and bearing frequencies, are presented. Furthermore, an overview of the new functionalities on the new system level in KISSsoft is provided, including:

1.Basic theoretical background on:

- characteristic gear mesh frequencies

- characteristic bearing frequencies

- Usage of characteristic frequencies in:

- the design phase of a system gearbox

- condition monitoring of gearbox

现在查看